PRODUCTS

Shandong Qifa Pharmaceutical Co., Ltd.

- Categories:Success case

- Author:

- Origin:

- Time of issue:2013-11-29

- Views:0

Shandong Qifa Pharmaceutical Co., Ltd.

(Summary description)Soft start (softstart) is a novel motor control device that integrates motor soft start, soft stop, light load energy saving and multiple protection functions.

- Categories:Success case

- Author:

- Origin:

- Time of issue:2013-11-29

- Views:0

introduction

Soft start is a novel motor control device that integrates motor soft start, soft stop, light load energy saving and multiple protection functions. The difference between soft start and traditional decompression start is:

No inrush current

When the soft starter starts the motor, the starting current of the motor linearly rises from zero to the set value. There is no impact on the motor, which improves the reliability of power supply, starts smoothly, reduces the impact torque on the load machinery, and prolongs the service life of the machine.

Soft parking function

That is, smooth deceleration and gradual shutdown. It can overcome the shortcomings of instantaneous power failure, reduce mechanical shock, avoid the water hammer effect of pump loads, and reduce equipment damage.

Adjustable starting parameters

According to the load situation and the power grid relay protection characteristics, it can be freely and steplessly adjusted to the best starting current.

1. Scheme selection

Finally, after communicating with Shandong Qifa Pharmaceutical Co., Ltd. in various aspects, we chose our company's GSDQ series of high-pressure water resistance soft starters. The main parameters of the field equipment are as follows:

Motor model: ASZK-LDAO4 (United States)

Rated power: 1100KW

Speed: 2965rpm

Rated voltage: 10KV

Rated current: 75.7A

Full voltage starting current double speed: 7.2 times

Whether the star point of the motor is turned on: No

Motor load: centrifugal compressor (refrigeration unit)

2. Working principle

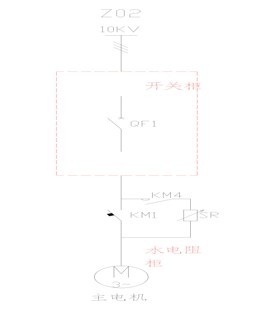

After the high-voltage switchgear is closed, the water resistance starter PLC (programmable controller) receives its auxiliary normally open contact closing signal (called start command), and after being arranged into a PLC logic judgment, the starter runs according to the program. At this time, the servo motor drives the transmission mechanism and the electrode plate to move downwards. The distance from the fixed electrode plate gradually decreases. The resistance value between the two electrode plates gradually decreases. The main motor gradually accelerates. When the movable electrode plate moves to the lower end, The resistance value is close to zero, and the vacuum switch is short-circuited to make the main motor run at full pressure, and at the same time the movable plate moves up to the upper end, ready for the next start.

3. Design features

The GSDQ series high-pressure water resistance soft starter used in this project has the following characteristics:

1) Good recoverability

The water tank has a large heat capacity, can be started continuously, will not burn out, and is easy to maintain. Even if part of the resistance fluid evaporates, it can be supplemented with water to restore its performance.

2) No harmonic pollution

The use of this device will not produce high-order harmonics, avoiding the pollution of the power grid.

3) The starting current can be controlled (the starting process can be controlled)

According to the actual working conditions of the load, the resistance value can be changed by adjusting and preparing the concentration of the electro-hydraulic, and the resistance value can also be changed by adjusting the spacing of the moving and fixed electrode plates. At the same time, the current negative feedback can be controlled by the PLC program to achieve The purpose of controlling the starting current.

4) Starting time can be adjusted

According to the actual working conditions and user requirements on site, the travel time of the moving plate can be changed by modifying the PLC control program, adjusting the initial starting position of the moving plate and adjusting the speed of the transmission motor to achieve the purpose of adjusting the starting time of the motor.

5) The starting process is smooth, and the starting operation switching has no impact

The linear movement of the movable plate makes the resistance of the series connected water resistance linearly reduced, so that the starting process of the motor is uniform, smooth and stepless; the water resistance value approaches zero at the moment of starting the switch, so the power grid is not affected when the switch is switched. Will produce current impact, and will not produce mechanical impact on the mechanical transmission system.

6) Current closed loop control

Current negative feedback closed-loop control can control the constant current starting of the motor and shorten the starting time.

4 Conclusion

Since the GSDQ series of high-pressure water resistance soft starters were put into use in Qifa Pharmaceutical, the equipment has been operating in good condition, fully achieving the expected results, and the economic benefits are obvious.

Scan the QR code to read on your phone

Hot information

- Good news! Dayu Electric has been selected as a national pilot unit for standardization in high-end equipment manufacturing industry 2024-03-06

- Dayu Electric Union launches year-end warmth delivery activities 2024-01-23

- Energy saving renovation of Dayukou Chemical Company 2024-01-22

- Dayu Electric Union launches year-end warmth delivery activities 2024-01-22

- Thirty Years of Glory, Striving for a New Journey, Exhibition and Broadcasting of Advanced Model Figures | Wang Yihua: Committed to Innovation, Striving for Strength, and Enhancing Industrial Level 2023-12-22

Honorary

Dayu Electric Technology Co., Ltd

Share

Copyright: Dayu Electric Technology Co., Ltd 鄂ICP备11003701号-3 TEL:0712-2883450 Address: No. 2, Hangtian Avenue, Xiaogan, Hubei